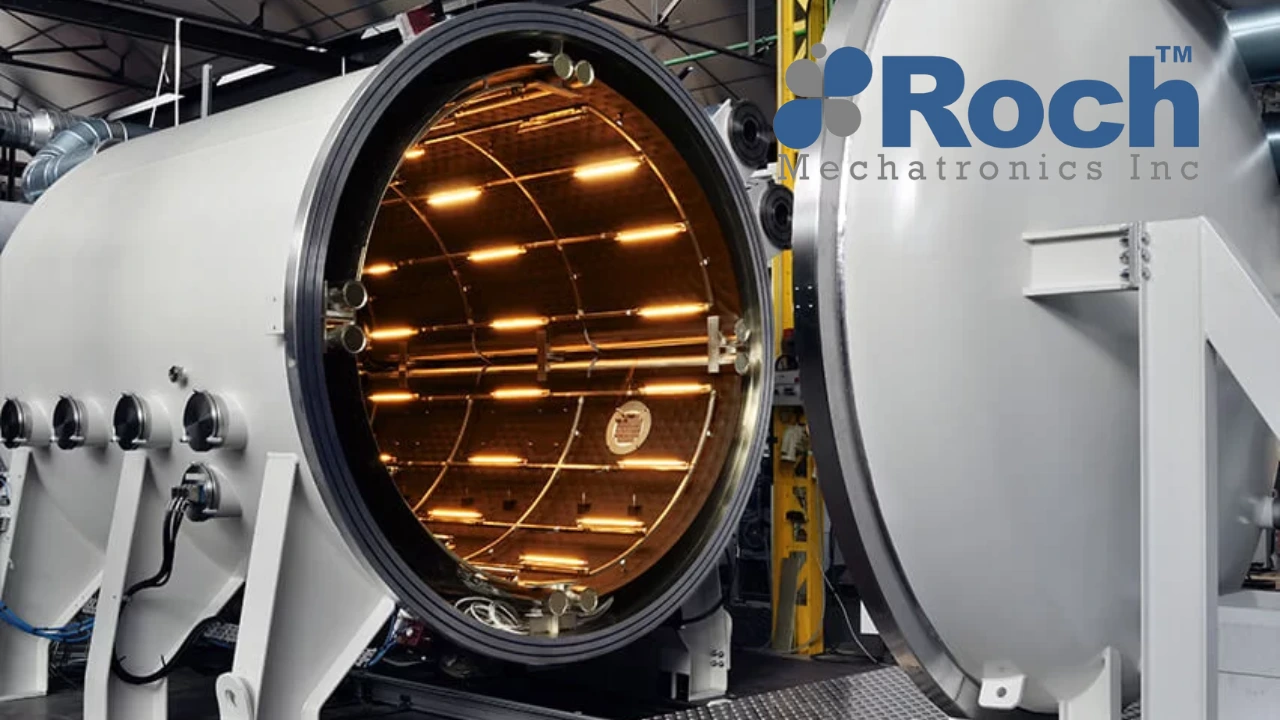

A Thermal vacuum chamber (TVAC) is a vacuum chamber in which the radiative thermal environment is controlled. A thermal vacuum chamber is a sealed, controlled environment used to simulate the vacuum conditions of outer space combined with extreme temperature fluctuations. This vacuum chamber is an essential tool used to simulate the extreme environmental conditions encountered in space, high-altitude environments, or harsh industrial settings. The external body of the vacuum chamber is usually made up of high-quality stainless steel to withstand the pressure difference between the internal & external atmosphere and to minimize the leak rates & outgassing for ensuring a deep vacuum inside the chamber. TVAC is characterized by being able to reach extreme temperature ranges ranging from -180 ° C to + 150 ° and by being able to reproduce equally extreme environments in terms of pressure, environments called “high vacuum”.

Also Read Us: What Is a Test Chamber and How Does it Work?

How Does a Thermal Vacuum Chamber Work?

Thermal vacuum chambers work by combining two critical environmental factors: vacuum and temperature control. Here’s how they function:

1. Creating a Vacuum

The first step in the process is creating a vacuum. A thermal vacuum chamber has powerful vacuum pumps that remove air from the chamber, simulating the vacuum conditions found in outer space. In space, there is no air, so creating a vacuum helps replicate these conditions on Earth.

The level of vacuum can be adjusted to mimic various atmospheric pressures, from a partial vacuum (for high-altitude simulations) to a near-complete vacuum (to simulate space conditions). The chamber can typically reach pressure levels as low as 10^-6 torr or even lower, depending on the specifications.

2. Temperature Control

Once the vacuum is established, the next step is regulating the temperature inside the chamber. Thermal control is achieved using both heating elements and cooling systems.

- Heating Elements: The chamber contains heating systems that simulate the high temperatures found in space or extreme conditions on Earth. For example, when a spacecraft is exposed to sunlight in space, it can reach extremely high temperatures. The heating elements replicate this by raising the temperature within the chamber to simulate those harsh conditions.

- Cooling Systems: On the flip side, space and high-altitude conditions also expose objects to extreme cold. The cooling systems in the chamber lower the temperature to simulate the freezing conditions that objects encounter in space, where temperatures can plummet to -250°F (-157°C). The chamber can replicate these low temperatures as needed for testing.

The temperature inside a thermal vacuum chamber can be controlled over a wide range, from -250°F to 250°F (-157°C to 120°C), depending on the test requirements.

3. Simulating Space-like Conditions

Together, the vacuum and temperature control simulate the combined effects of space-like conditions. Objects inside the chamber are exposed to both the lack of air (vacuum) and extreme temperature changes, just like they would experience in outer space or other hostile environments. For instance, satellites in space are subjected to fluctuating temperatures as they move between the sun’s heat and the cold of shadowed regions, and thermal vacuum chambers replicate these changes.

This makes it possible for engineers to evaluate how components, such as electronics, materials, and systems, will behave under extreme conditions before they are deployed in space or high-risk environments.

4. Testing and Data Collection

During testing, sensors within the chamber monitor key variables, such as pressure, temperature, and humidity. These sensors provide real-time data that engineers use to assess how well the components or materials perform under simulated space or environmental conditions.

The data collected during tests helps identify potential weaknesses, failures, or areas for improvement in the tested components. For example, it can reveal how electronics behave when exposed to thermal stress or how materials react to the vacuum and temperature extremes of space.

Applications of Thermal Vacuum Chambers

Thermal vacuum chambers are used in a variety of industries, each with its specific requirements for testing components or systems. Here are some of the most common applications:

- Aerospace and Space Exploration

- Thermal vacuum chambers are essential for testing spacecraft, satellites, and space equipment. They simulate the harsh environment of space, where components are exposed to temperature extremes and vacuum conditions. Engineers at Roch Mechatronics Inc. provide chambers that ensure components such as rocket parts, space probes, and satellite systems are thoroughly tested for reliability in space.

- Thermal vacuum chambers are essential for testing spacecraft, satellites, and space equipment. They simulate the harsh environment of space, where components are exposed to temperature extremes and vacuum conditions. Engineers at Roch Mechatronics Inc. provide chambers that ensure components such as rocket parts, space probes, and satellite systems are thoroughly tested for reliability in space.

- Electronics Testing

- Many electronics components, such as circuit boards, semiconductors, and sensors, are tested in thermal vacuum chambers to ensure they can withstand extreme temperature variations and the vacuum conditions they may face in space. Our chambers help ensure that space missions or satellite systems maintain functionality under space conditions.

- Many electronics components, such as circuit boards, semiconductors, and sensors, are tested in thermal vacuum chambers to ensure they can withstand extreme temperature variations and the vacuum conditions they may face in space. Our chambers help ensure that space missions or satellite systems maintain functionality under space conditions.

- Material Science

- Researchers use thermal vacuum chambers to study how materials behave under extreme temperatures and low pressure. This helps in the development of new materials and technologies for industries such as aerospace, automotive, and energy.

- Researchers use thermal vacuum chambers to study how materials behave under extreme temperatures and low pressure. This helps in the development of new materials and technologies for industries such as aerospace, automotive, and energy.

- Automotive and Aviation

- In the automotive and aviation industries, thermal vacuum chambers test parts that may be exposed to high-altitude conditions or extreme temperatures. This ensures that materials, coatings, and electronic systems remain functional under challenging conditions.

- In the automotive and aviation industries, thermal vacuum chambers test parts that may be exposed to high-altitude conditions or extreme temperatures. This ensures that materials, coatings, and electronic systems remain functional under challenging conditions.

- Military and Defense

- The military relies on thermal vacuum chambers to test equipment and systems used in defense applications, ensuring they can endure the harsh conditions faced in high-altitude, remote, or space environments.

- The military relies on thermal vacuum chambers to test equipment and systems used in defense applications, ensuring they can endure the harsh conditions faced in high-altitude, remote, or space environments.

Why Choose Roch Mechatronics Inc. for Thermal Vacuum Chambers?

At Roch Mechatronics Inc., we specialize in designing and manufacturing high-performance thermal vacuum chambers that meet the exacting standards of various industries. We are one of the leading Test Chamber Manufacturers in India. We are highly focused on our product quality. Our chambers offer:

- Precise Control: Our thermal vacuum chambers allow for fine-tuned control over both temperature and pressure, enabling accurate simulations of space or environmental conditions.

- Durability and Reliability: Built with high-quality materials, our chambers are engineered for long-lasting performance, even under rigorous testing conditions.

- Customization: We offer tailored solutions to meet the unique needs of your testing process, ensuring optimal results for your specific applications.

- Expert Support: Our team of experts provides comprehensive support, from installation to operation, ensuring seamless integration of our thermal vacuum chambers into your testing processes.

If you are looking for a Test Chamber Manufacturer, Roch Mechatronics is here to provide the best chambers. We have manufactured various kinds of test chambers such as Plant growth test chamber, Thermal Vacuum Chamber, Growth Chamber, Environmental test chamber and more. If you have any need related to chamber, The best Test chamber manufacturer in India Roch Mechatronics is the perfect choice for you. Feel free to contact us and know more about us.