Test chambers are essential tools across industries for evaluating the durability, performance, and reliability of products under various environmental conditions. Choosing the right test chamber depends on the specific needs of your product testing, as each type serves different purposes. Here’s an overview of the primary types of test chambers and their applications to help you determine which one suits your needs best:

1. Environmental Test Chambers

- Purpose: Simulate extreme environmental conditions, including temperature, humidity, and altitude.

- Applications: Commonly used in electronics, automotive, and aerospace industries to test components’ resilience to harsh conditions.

- Key Features: Range of temperature and humidity controls; some models offer combined temperature and humidity testing to mimic real-world environments more accurately.

- Purpose: Test materials and components under extreme hot or cold temperatures.

- Applications: Ideal for evaluating materials’ performance and thermal resistance in fields like electronics, automotive, and material science.

- Key Features: Adjustable temperature ranges; some models reach as low as -80°C or as high as +300°C for precise thermal testing.

- Purpose: Expose products to varying humidity levels to test for moisture tolerance and degradation.

- Applications: Useful for testing products prone to moisture damage, such as textiles, coatings, and electronic components.

- Key Features: Precise humidity control from low to high ranges; often integrated with temperature control for combined testing.

- Purpose: Rapidly shift between high and low temperatures to test material durability under sudden environmental changes.

- Applications: Primarily used in electronics, aerospace, and automotive sectors to test components’ ability to withstand rapid thermal transitions.

- Key Features: Dual chambers (hot and cold zones) for fast temperature cycling; essential for assessing the thermal expansion and contraction of materials.

- Purpose: Simulate salt-rich environments to test the corrosion resistance of products.

- Applications: Popular in marine, automotive, and construction industries to test coatings, paints, and metals.

- Key Features: Sprays a salt solution onto the product; offers variable control over exposure time and concentration to measure corrosion rate accurately.

- Purpose: Expose products to mechanical vibrations to simulate real-world wear and tear.

- Applications: Used for automotive parts, electronics, and heavy machinery components to test for structural integrity under physical stress.

- Key Features: Adjustable vibration patterns and intensity to mimic different types of movements, including random or repetitive vibration sequences.

- Purpose: Simulate high-altitude conditions with low air pressure and oxygen levels.

- Applications: Essential for aerospace, automotive, and defense sectors where components are tested for performance in high-altitude or low-pressure environments.

- Key Features: Allows users to control altitude, temperature, and humidity simultaneously to mimic extreme elevation conditions.

- Purpose: Designed to create a soundproof and echo-free environment for acoustics testing.

- Applications: Commonly used in audio engineering, telecommunications, and electronics to measure noise levels and sound quality.

- Key Features: Walls lined with absorbent material to prevent sound reflection; some chambers have electromagnetic shielding to test RF emissions.

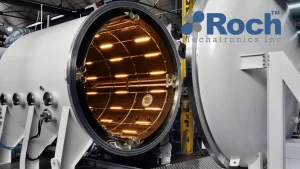

- Purpose: Remove air and simulate a vacuum environment.

- Applications: Used in aerospace, electronics, and materials science to test how materials and components behave in low-pressure or space-like conditions.

- Key Features: Strong, airtight structure; variable vacuum levels for testing different pressure environments.

Choosing the Right Test Chamber

When selecting a test chamber, consider:

- Product Requirements: Understand the specific conditions your product will face in its intended use.

- Environmental Needs: Choose a chamber that replicates the exact environment your product is designed for, whether that’s high humidity, temperature extremes, or high-vibration scenarios.

- Regulatory Standards: Ensure the test chamber complies with industry standards that may be required for regulatory approval or certification.

Finding the right test chamber depends on your product’s unique requirements and your industry’s demands. With the right chamber, you’ll ensure more reliable, robust products for the market.

About Roch Mechatronics Inc.:

Roch Mechatronics Inc., located in Ghaziabad, Uttar Pradesh, is a leading manufacturer of Test Chamber. Renowned for our exceptional quality and client satisfaction, we specialize in Test Chamber, Environmental Chamber, Humidity Chamber and Walk-in Chamber. Our standout feature is our 24/7 customer support, ensuring you always have assistance when needed. For inquiries or support, call us at +91-7011654652 or email info@rochmechatronics.com, rochmechatronicsinc@gmail.com